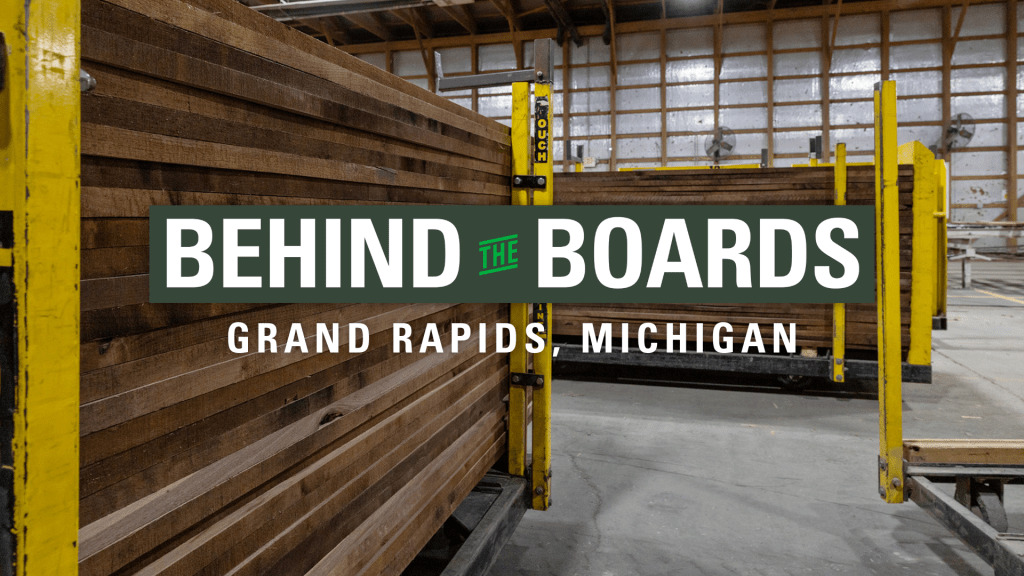

A Concentration Yard with Distinct Capabilities

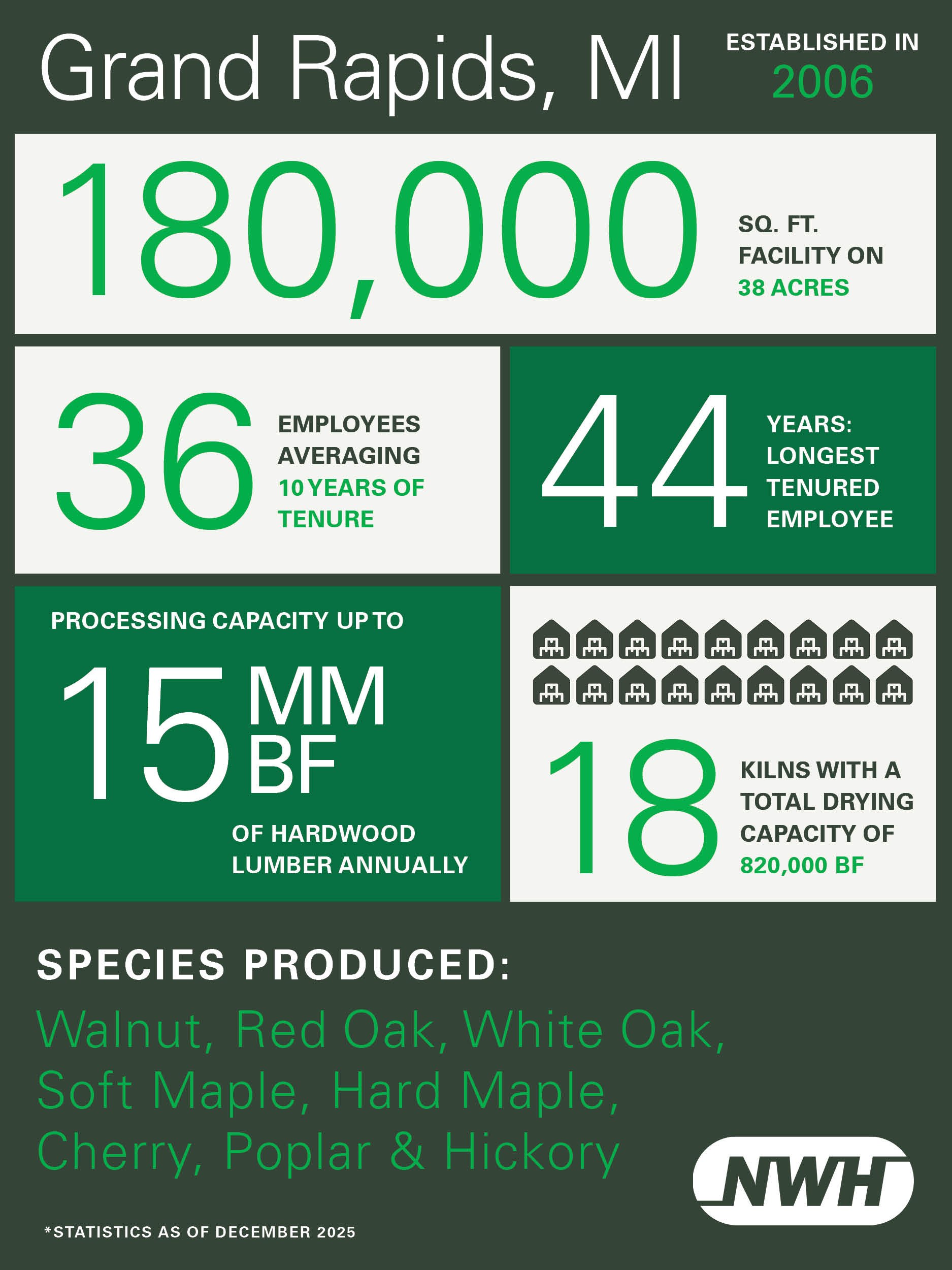

Originally Budres Lumber before being purchased by Weyerhaeuser in 2006, the Grand Rapids site has grown into a major NWH operation. Today, the facility spans 38 acres with an estimated 180,000 square feet under roof—not including its extensive kiln capacity. The site houses 18 kilns with a total capacity of 820 MBF and produces approximately 15 million board feet of kiln-dried lumber annually.

The yard handles a wide range of species, including Walnut, Red Oak, White Oak, Soft Maple, Hard Maple, Cherry, Poplar, and Hickory.

What sets this yard apart is its specialized equipment:

- A steamer, which is a unique feature for a concentration yard, allowing the team to steam Walnut to enhance color consistency.

- A four-head abrasive planer, uncommon in the region, which helps refine lumber color and overall appearance before shipping.

These capabilities allow the Grand Rapids team to deliver exceptionally consistent and high-value hardwoods—particularly important for premium species like Walnut and White Oak.

A Strong Culture That Drives Success

The Grand Rapids facility is powered by a team of 36 employees with an average tenure of 10 years. That depth of experience creates a culture built on pride, accountability, and shared responsibility.

The team is known for stepping outside traditional job roles whenever needed—filling in, taking on new tasks, and supporting each other to ensure production stays on track and high-quality is maintained. With valuable species moving through every stage of the process, protecting quality from the air-dry yard through the kilns, planers, sanders, and shipping is a central focus.

People Who Make the Difference

The site’s longest-tenured employee, Doug “Bud” Goodwin, has worked at the facility for 44 years, dating back to the Budres Lumber days. Over the decades, Bud has done nearly every forklift job onsite—from stacker to kilns to the planer—and even drove a semi delivering lumber in earlier years. Today, he serves in shipping, where he’s worked for about 20 years.

His advice to new team members is simple and timeless:

“Pay attention to everything and all the details. There’s a reason for the way we do things and how we do things matters—doing it right the first time is always best.”

Bud says his favorite thing about NWH is the variety:

“No two days are the same. There’s always a new task or challenge, and opportunities to learn other parts of the operation.”

Leadership at the site mirrors that blend of experience and adaptability.

Mill Manager Jeremy Long brings more than 15 years with NWH, including significant experience in Quality Control at our Eugene, Oregon facility. His deep understanding of milling processes and his hands-on approach support both quality and communication across the team.

Production Manager Joseph “Joe” Wiest began on the pull chain in 2007 and worked his way up through lumber grading, tally, reman, QC backup, and multiple yard roles.

“My favorite part of working at NWH is the opportunities for growth and career development,” Joe says—a sentiment that reflects both his own path and the culture of the site.

What Makes Grand Rapids Special?

With a strong team, specialized equipment, and a shared commitment to producing the highest-quality hardwood lumber, the Grand Rapids facility continues to play an essential role in Northwest Hardwoods’ operations. The yard’s dedication to craftsmanship, teamwork, and innovation ensures customers receive consistent, premium hardwood products—every load, every time.

Grand Rapids is a place with a presidential legacy. It was the childhood home of Gerald Ford—the only U.S. President to take office without receiving a single electoral vote, following the resignation of President Richard Nixon. The city proudly honors its native son with the Gerald R. Ford Presidential Museum and the burial site of the former President and First Lady.

And the facility has its own memorable piece of local history: after a Detroit Red Wings’ Stanley Cup win, a connection inside the organization brought the Stanley Cup itself right onto the NWH yard—a moment the team still talks about today.

GRAND RAPIDS, MI

657 76th St SW

Byron Center, MI 49315

- Concentration Yard

Check out our other Behind the Boards spotlights, and stay tuned for more coming soon!

Behind the Boards: Longview, WA

Behind the Boards: Marienville, PA

Behind the Boards: Loudonville, OH

Behind the Boards: Grand Rapids, MI

Share This Post!