Graded For Yield: Our Contribution To Your Bottom Line

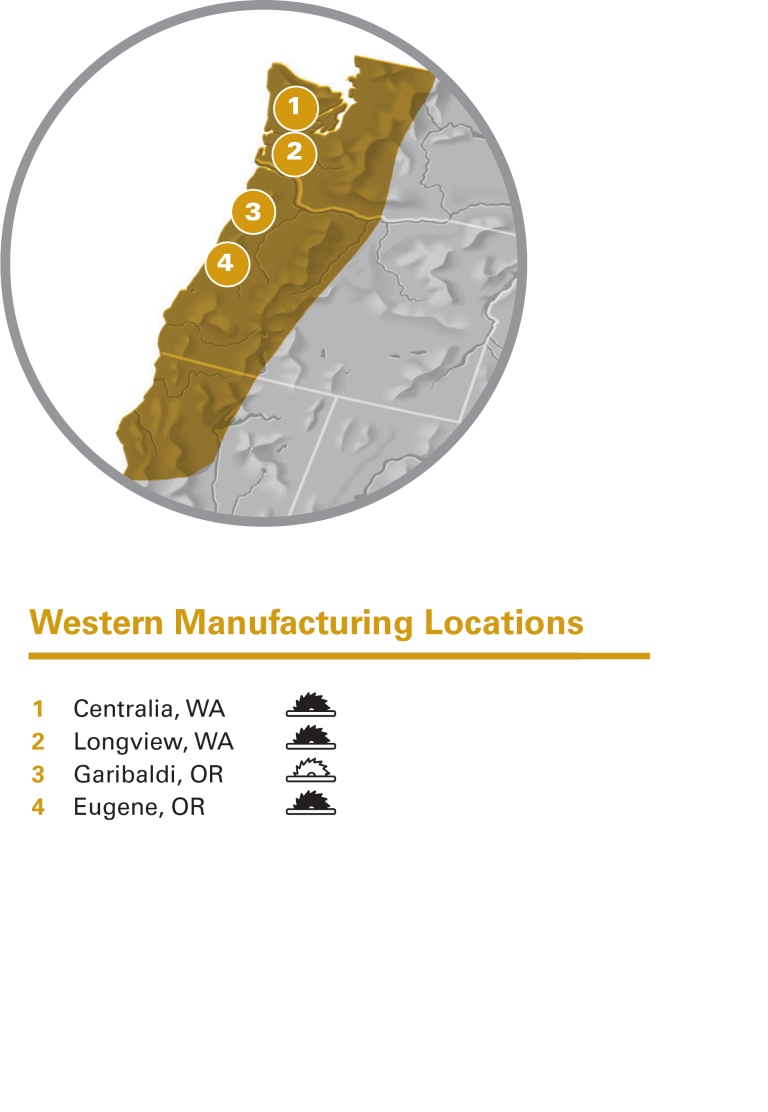

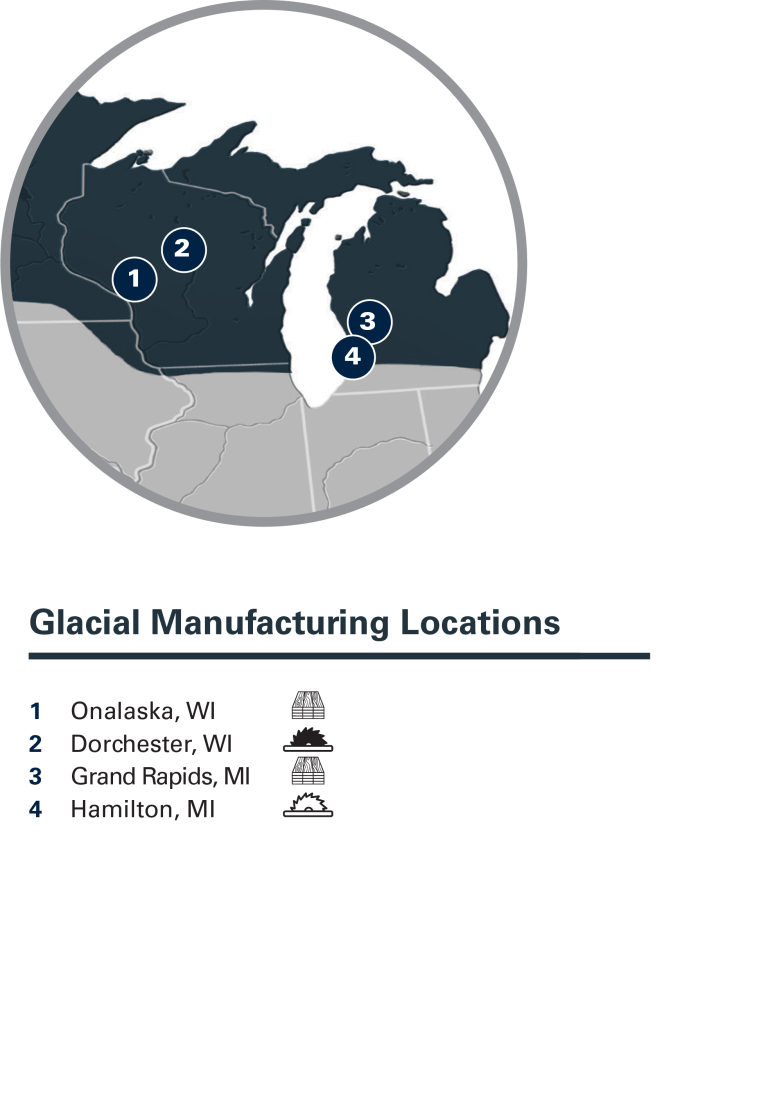

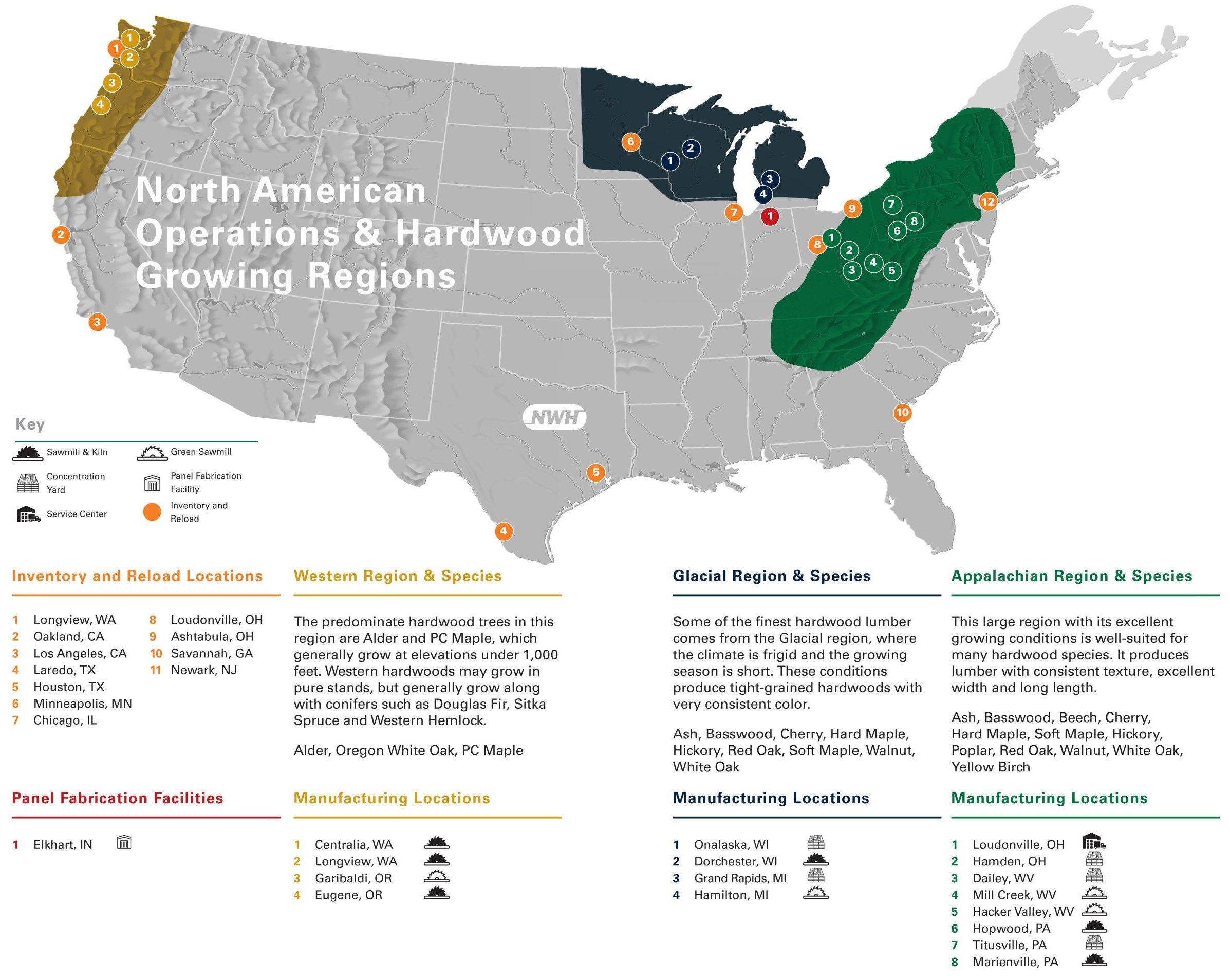

At NWH, we operate 19 locations, including mills, concentration yards, and re-manufacturing plants throughout the three major hardwood growing regions. We have 12 warehousing and distribution points strategically located throughout the United States. It’s all part of our continued commitment to making your hardwood supply chain as flexible as possible.

Double-cut bandmills and laser-guided scanning technology improve the yield of each log. The latest in kiln equipment, combined with our management and monitoring of the drying process, minimizes the number of defective boards and guarantees more consistency in moisture content. We grade after drying and surfacing to better account for defects. Our custom grading process is designed to help customers increase their profit margins. We offer lumber grades that are application specific to help customers minimize waste in their production process.

We guarantee responsible sourcing to better distinguish your offerings, which contributes significantly to building your customer base and helps you achieve high levels of productivity. Whether it be quality advice or quality materials, we are always here to help.

our contribution to your bottom line

At NWH, we operate 40-plus manufacturing locations, including mills, concentration yards, and re-manufacturing plants. We have 11 warehousing and distribution points strategically located throughout the United States. It’s all part of our continued commitment to making your hardwood supply chain as flexible as possible

Computer Controlled Drying

Our kiln operators use computerized controllers and proprietary drying techniques to monitor the drying process and to insure a rich…

see more >Headrig Sawing

Headrig sawing gets the very best lumber from a wide range of log types. Logs sent to the sawmill headrigs…

see more >Inspection & Grading

Graded for yield. In addition to standard NHLA grades, we have developed a proprietary grading system based on application designed…

see more >Log Decks

Large log decks make sure that the mill never runs out of raw logs to process. Log stock is rotated…

see more >Log Supply

A constant flow of quality hardwood logs enter our mills daily. We buy logs from private landowners as well as…

see more >Shipping Worldwide

We are shipping quality hardwood lumber worldwide to an impressive list of new and long-term clients. The shipping department organizes,…

see more >Sorting & Stacking

Sorting and stacking conditions the lumber. Lumber is sorted by thickness and length and sent to the stacker. The stacker…

see more >Surfacing

Surfacing provides a finished-thickness product ready to be inputted into our customer’s manufacturing processes. The most common request in terms…

see more >