Aesthetic Appeal: Warm, Clean, and Versatile

When it comes to visual impact, Alder is hard to beat. Unlike the pale, ray-flecked European Beech that complicates finishing and can appear visually overwhelming, Alder offers a clean, consistent look that suits various design styles.

Alder’s natural warm tone adds an inviting ambiance, perfect for spaces that aim for a cozy and timeless feel. Combined with its subtle grain pattern, Alder is adaptable to both traditional and contemporary aesthetics. Plus, Alder’s ability to take stains and finishes beautifully enhances its appeal, allowing for versatile and creative design possibilities.

Stability and Reliability: Minimize Issues, Maximize Results

Working with European Beech comes with its fair share of challenges. Its strong internal tension can lead to warping and twisting, which compromise product quality and often result in wasted material.

Alder, however, delivers exceptional stability, maintaining minimal movement after drying and conditioning. This reliable stability provides:

- Flatter, straighter boards, reducing waste and making production more predictable.

- Consistent quality, leading to fewer complications during processing.

- Efficient planning and higher-quality results, giving manufacturers confidence in their production processes.

Smooth Workability and Reduced Tool Wear

For manufacturers, the workability of the material can make a significant difference in production efficiency. Alder is known for its smooth processing and machining, which makes it a very user-friendly option. Unlike European Beech, Alder’s properties lead to less tool wear, extending the life of machinery and lowering maintenance costs. This level of efficiency not only improves the manufacturing experience but also makes Alder a cost-effective choice over time.

Economic Advantages: Affordable and Predictable

In a market that can be unpredictable, having a reliable material source is crucial. Consider the benefits of Alder over European Beech:

- Lower transportation costs: Unlike European Beech, which is largely imported, Alder is sourced locally within the U.S., reducing transportation expenses.

- Quicker, more reliable procurement: With Alder being domestically sourced, manufacturers experience fewer delays and disruptions to production schedules.

- Consistent availability: Alder’s reliable supply ensures stable pricing, even during market volatility.

- Effective budgeting: The stable pricing of Alder helps manufacturers plan budgets more effectively and avoid costly production downtime.

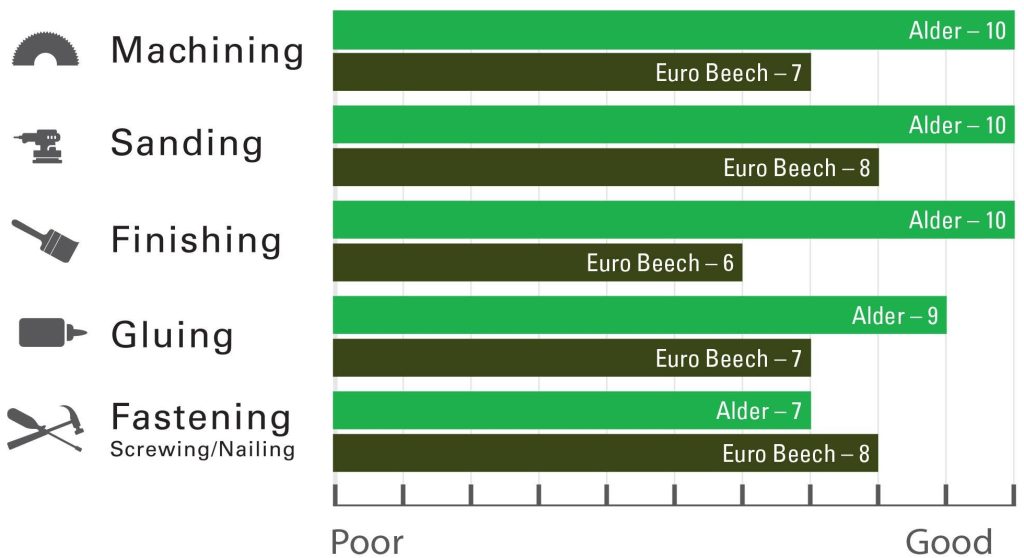

Species Comparison Chart

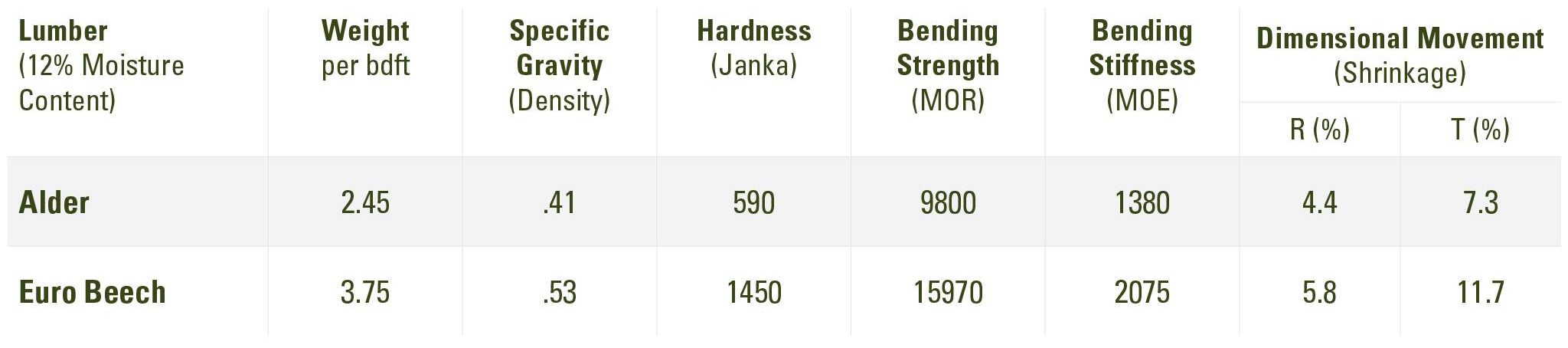

Species Comparison Data

Source: The Wood Database

A Sustainable Choice for a Better Future

Alder supports sustainable American forestry, promoting responsible land management practices that benefit both the environment and local economies. Additionally, Alder’s domestic supply reduces the carbon footprint associated with long-distance transportation, making it an eco-friendly alternative to imported European Beech. With the availability of European Beech threatened by climate challenges, Alder offers a resilient and sustainable option that aligns with environmentally conscious manufacturing goals.

Discover the Benefits of Alder

Choosing the right wood can make all the difference in strengthening a manufacturing process from challenging to smooth. Alder stands out as a smart alternative to European Beech, offering warm aesthetics, consistent quality, easy workability, cost-effectiveness, and a sustainable edge.

Resources

Feature Image: Alder Millwork, Crystal Cabinets, design by Nor-Son Inc.

Share This Post!