If you’re thinking of trying a new wood species for a project, research is key to your success. Choosing the best wood material for the job requires more than evaluating options based on looks, durability and grade—it’s also important to consider stability. Knowing how stable a species is helps you avoid potential problems down the road.

But, did you know that a wood’s stability depends on more than how it was grown or what species it is? How a supplier mills, dries and stores its lumber also influences stability—and not all wood species can follow the same protocols.

It’s easy to research wood species’ working properties, aesthetic characteristics, and hardness, but when it comes to the drying schedule, that information is hard to find—and often proprietary. If you do obtain it, it may not be clear how those protocols impact stability.

“You don’t want a situation where you use a wood one time, and it’s stable. But the next time you use it, it isn’t,” says Don Barton, Vice President of Sales & Marketing for Northwest Hardwoods. “Manufacturers need to be able to trust their predictions about a wood species before they go ahead and use it to create a product.”

Obtaining this kind of predictability requires more than measuring moisture content after kiln-drying. It requires measurement of average and standard deviation of types of warping that occur, such as bow and crook.

That’s why, said Don, when one of his customers wanted to use Pacific Coast Maple for a new application, Northwest Hardwoods decided to first put it to the test.

Modifying and testing drying protocols for Pacific Coast maple

Until recently, Northwest Hardwoods dried its Pacific Coast Maple on a shorter schedule than eastern Soft Maple. With similar density to its eastern cousin, Pacific Coast Maple (Acer Macrophyllum, also known as big leaf maple, and Oregon maple) was prone to stability issues such as bow and crook due to the shorter drying time.

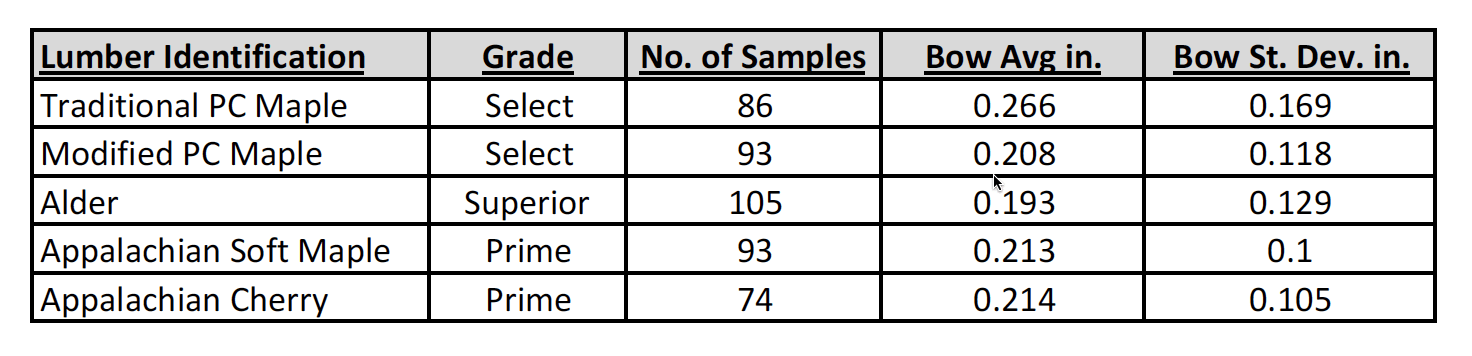

After modifying the Pacific Coast maple drying protocols—including humidity, drying time, temperature, and conditioning—to try to achieve greater stability, Northwest Hardwoods brought in George Woodson of Woodson Wood Technology, LLC to test the results. In the chart below you can see the results of this test.

For this study, completed on April 1, 2017, Woodson compared two different drying schedules—Traditional and Modified—for Select Grade Pacific Coast maple (PCM). To provide a comparison of how the PCM would measure up against common alternative materials, the study also measured bow and crook in Superior Grade red alder, Prime Grade Appalachian soft maple, and Prime Grade Appalachian cherry—all dried on their respective traditional schedules.

The modified drying protocols yielded wood with 21.8% less average bow than traditionally dried Pacific Coast maple—comparable to the average bow found in alder, Appalachian Soft Maple and Appalachian Cherry lumber. Average crook was down 26.2%—bringing it on a par with its eastern counterpart.

Test results inform new applications

The testing demonstrated that the new drying protocols allow Northwest Hardwoods to provide a more stable wood comparable to alder, Appalachian Soft Maple and Appalachian Cherry and suitable for applications such as kitchen cabinetry, furniture and door manufacturing.

“Testing like this provides peace of mind for a manufacturer,” said Don. “You know before you buy the Pacific Coast Maple that it will perform well”.

“I tell everyone, ‘If you’re unsure about the species you’re considering, ask for its stability test results,’” he continued. “You want to be able to validate that this species’ performance is similar to what you’re used to and what you expect.”