We take pride in our implementation of modern technology at Northwest Hardwoods. It’s not just about cutting costs—our technologically-based systems allow us to minimize waste, increase employee safety, ensure the consistent quality of our products, and improve the overall customer experience.

The lumber industry isn’t exactly new. Its significant history in the United States dates to the founding of the original colonies in the early 17th century . Since then, lumber workers have sought ways to maximize yield and minimize risk and waste.

“It all starts in the log yard,” says Steve Baker, Manufacturing Manager at the Marienville, PA facility. Each arriving log is individually catalogued with a handheld computer scanner, he explains, in order to later generate reports concerning “where the logs come from, the profitability of a particular tract of timber, [and] the species mixes that are on site.” This technology improves the efficiency of the log scalers and allows for a better understanding of what is entering the mill.

“It all starts in the log yard,” says Steve Baker, Manufacturing Manager at the Marienville, PA facility. Each arriving log is individually catalogued with a handheld computer scanner, he explains, in order to later generate reports concerning “where the logs come from, the profitability of a particular tract of timber, [and] the species mixes that are on site.” This technology improves the efficiency of the log scalers and allows for a better understanding of what is entering the mill.

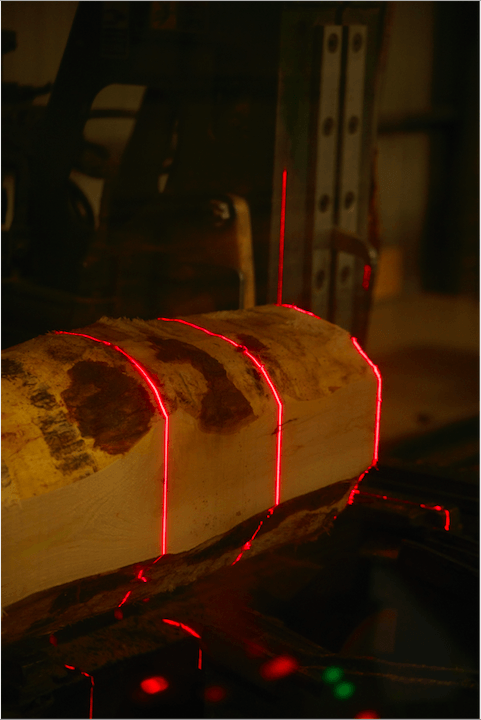

But the technological advancements go beyond simply cataloguing and report generation. In nearly all Northwest Hardwoods mills the next major innovation lies at the headrig where logs are squared and cut into boards. At this stage, the machine scans and measures the shape of the logs to determine the depth for the opening face and automatically brings each log into optimal position. Ensuring this first cut is neither too shallow nor too deep is “critical” to maximizing yield, explains Baker, and “the more un-uniform the log is, the more valuable that tool is.”

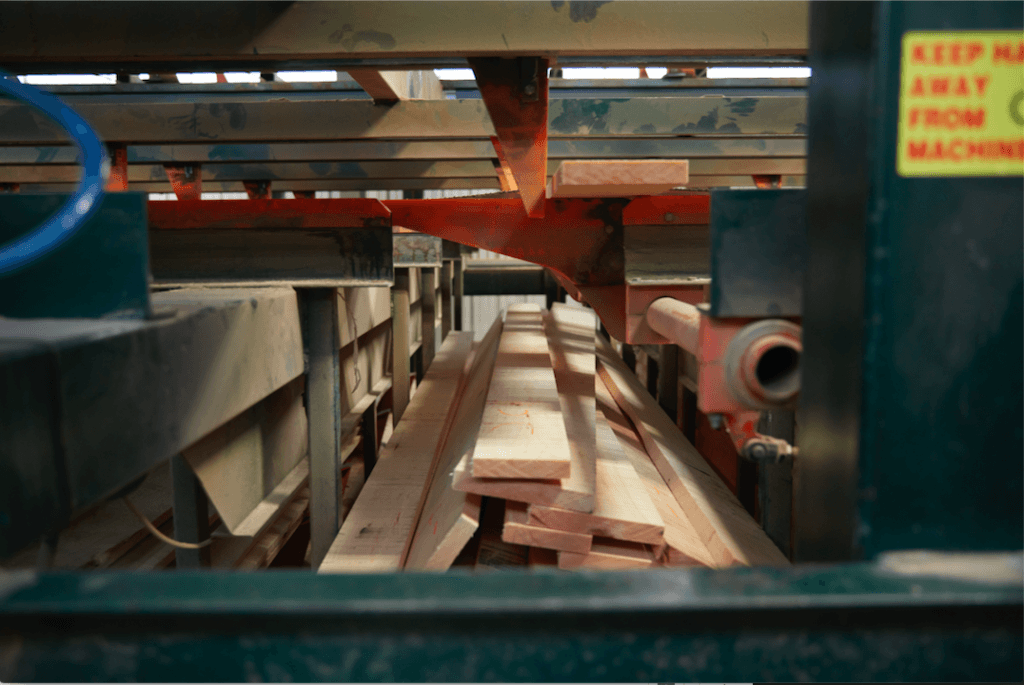

A similar system works to optimally edge the boards by identifying the shape of the board and setting the saw. A major advantage of these machines is that they make it easier and faster to identify any trending issues or mistakes, so that corrections and be made swiftly and effectively to ensure a consistent product.

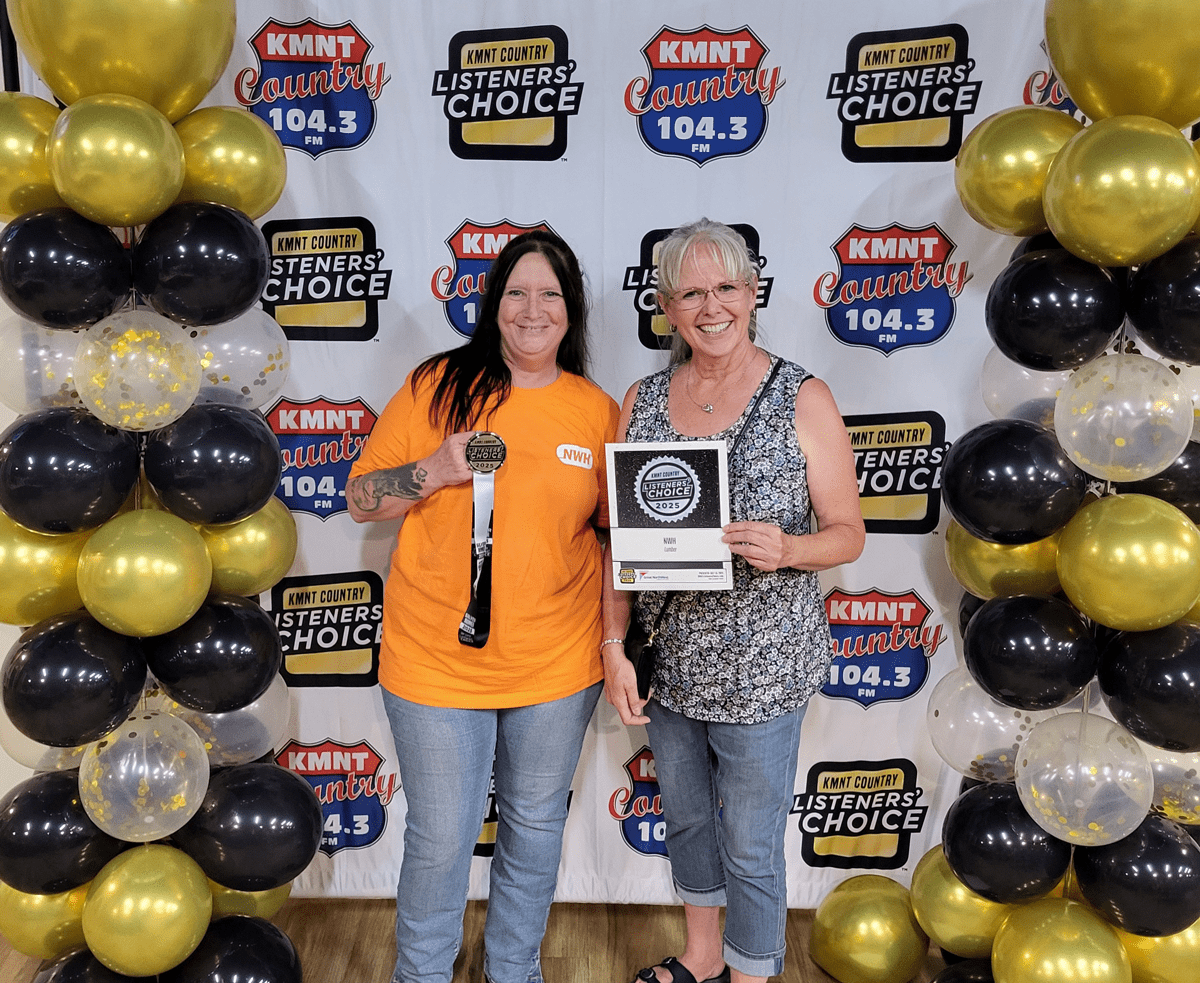

Once the boards have been edged, the last major step is for them to be graded and sorted. Grade inspectors manually mark each board with color-coded symbols to start the sorting process. But making sure the boards get to the right place can be difficult, and sometimes dangerous. That’s part of the reason why, at the Marienville facility for instance, we employ a machine that scans each board to read the symbol and automatically sort it to one of 60 bins depending on grade, width or length. In addition to making it safer and easier to sort the boards, this system also provides an “extremely accurate tally of the footage of lumber” says Baker, which makes it easier to talk with customers about what’s available and to pull exactly the right product for customers.

The Marienville facility, which was built in 2000 with the scanning technologies, is “in the top 20%… industry-wide” as far as its technological use, estimates Baker, who notes that “there are a lot of smaller mills that do everything in a very old-fashioned, very manually-oriented way, with almost no technology.” But in today’s competitive market, Baker thinks this technology is more than just helpful, it’s “almost mandatory.” Without the headrig scanner, for instance, he says, “we would not be able to compete when we buy timber, we just couldn’t get the yield out of the logs.”

As industry technology continues to develop, we’ll likely see a rising demand for automation with the intent of improving efficiency and consistency. But the bigger picture, and our focus at Northwest Hardwoods, is the value of the data from new technology: data that lets us do more with what we already have, rather than simply speeding up the milling process. Keeping our mills outfitted with leading technologies will ensure we continue to provide the highest quality products consistently, efficiently, and sustainably.

Share This Post!